|

GM literature states, "Convertible top: White (Regular

Production), Black or Medium Blue (RPO C05) were available with any exterior

color." The convertible top was available with both manual and power versions.

The numbers below appear on the Fisher Body Plate to

identify color of convertible/vinyl top.

|

COLOR

|

CONVERTIBLE TOP COLORS |

| |

1 ~ White (standard) |

| |

2 ~ Black |

| |

4 ~ Medium Blue |

|

GM literature states, "Vinyl top option

(RPO C08): Black or Lt. Fawn with any exterior color."

|

|

COLOR

|

VINYL TOP COLORS |

| |

2 ~ Black |

| |

6 ~ Light Fawn |

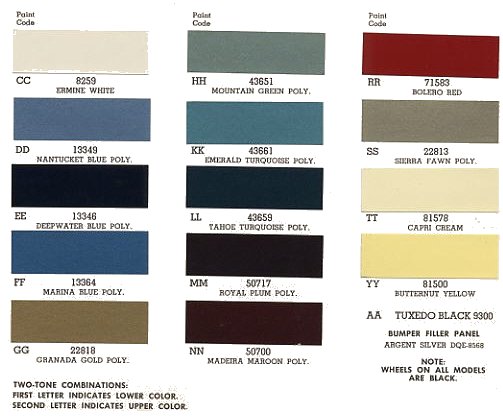

U.S. Paint Code Chart

GM of Canada Paint Code Chart

|

General Motors of Canada LTD offered many

of the same colors as their U.S. counterpart with three additional

colors available (noted with asterisk), Verde Green Metallic,

Silver Glaze Metallic, and Antique Pewter

Metallic. Several other Canadian colors were identical

to U.S. colors, only the names were a bit different.

|

| Color |

Color Name |

Paint Code |

|

|

Enamel |

Lacquer |

| |

Tuxedo Black |

A |

3A |

| |

Provincial White |

C |

3C |

| |

Nantucket Blue Metallic |

D |

3D |

| |

Deepwater Blue Metallic |

E |

3E |

| |

Marina Blue Metallic |

F |

3F |

| |

Grenada Gold Metallic |

G |

3G |

| |

Mountain Green Metallic |

H |

3H |

| |

Verde Green Metallic* |

J |

3J |

| |

Emerald Turquoise Metallic |

K |

3K |

| |

Tahoe Turquoise Metallic |

L |

3L |

| |

Plum Mist Metallic |

M |

3M |

| |

Madeira Maroon Metallic |

N |

3N |

| |

Silver Glaze Metallic* |

P |

3P |

| |

Bolero Red |

R |

3R |

| |

Sierra Fawn Metallic |

S |

3S |

| |

Capri Cream |

T |

3T |

| |

Antique Pewter Metallic* |

V |

3V |

| |

Butternut Yellow |

Y |

3Y |

|

Paint Process

-

RUSTPROOFING: Assembled car bodies

are chemically sprayed to clean and etch the metal surfaces

for corrosion resistance and paint adhesion. Unassembled

sheet metal parts follow the same process.

-

BODY AND SHEET METAL PRIMERS: Four

corrosion resistant primers, especially formulated,

are hand sprayed on the body in areas where rust might

develop. Lower areas considered especially vulnerable

are coated with another rust inhibiting compound.

-

PRIMER COAT is applied to all outside

and inside surfaces of front fenders and hoods. The

parts are mechanically dipped or flow-coated to insure

coating in all seams and secluded areas and baked at

390 degrees F. for 30 minutes. A coat of sealer is then

applied by hand spray to all surfaces requiring another

coat of lacquer.

-

FLASH PRIMER AND PRIMER-SURFACER

COATS: An air-dry flash primer coat is hand sprayed

on surfaces below the body belt line. Then a gray primer-surfacer

coat is hand sprayed on all outside surfaces of the

body and oven baked for 45 minutes at 285 degrees F.

-

INITIAL SANDING: Power wet sanding,

followed by hand sanding, is done on all body surfaces

requiring lacquering. This ensures a smooth surface

for the lacquer finish. to remove the water, the body

is wiped and run through an infra-red oven.

-

LACQUERING: Three coats of acrylic

lacquer are spread on the exterior surfaces of the body

and sheet metal parts to build up a finish of the required

thickness for each color.

-

INITIAL BAKING: To harden the paint

for final sanding, the body and sheet metal parts are

baked for approximately 10 minutes at 200 degrees F.

-

FINAL SANDING: To remove body surface

defects, power and hand sanding is done with fine grit

sandpaper and mineral spirits as a wetting agent. Sanded

areas are wiped to insure a clean surface before final

baking.

-

FINAL BAKING: To assure a durable,

hard, high luster finish the lacquer is baked for 30

minutes at 275 degrees F. Reheating the lacquer after

final sanding permits paint film to soften, allowing

surface blemishes and sanding scratches to disappear

during the thermo-reflow process.

-

UNDERCOATING: To block out road noise,

an asbestos fiber sound deadener with asphalt base is

sprayed inside the wheel housings and on the bottom

of the underbody at designated areas.

-

PAINT REPAIR AND PROTECTION: Mars,

nicks, or scratches that occur during final assembly

are corrected at the factory before shipment. When required,

light "slush" polishing brings painted surfaces to a

high luster finish. Wax is applied to all horizontal

surfaces of each vehicle and polished out for protection

during shipment. The wax contains no silicones, thus

eliminating any paint contamination problem.

|

|

|